Stainless steel is one of the most popular materials in the industrial as well as commercial manufacturing industry. Its excellent properties like remarkable strength, high ductility, high-temperature sustainability, lustrous finish, and corrosion resistance make it the perfect material for manufacturing a wide range of products for diverse applications.

Metal Casting

Metal casting is one of the most common methods used in steel manufacturing. It is a process that uses molten metal to form the desired shape. This method starts by pouring liquid metal into a mold. The steel is cooled and solidified, and then cut out and finished with milling processes before it is ready for use.

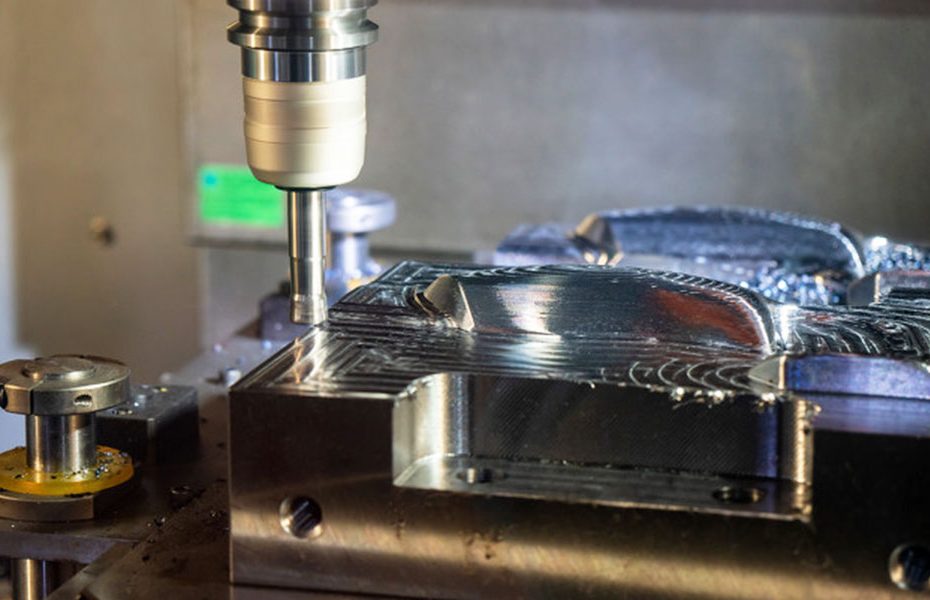

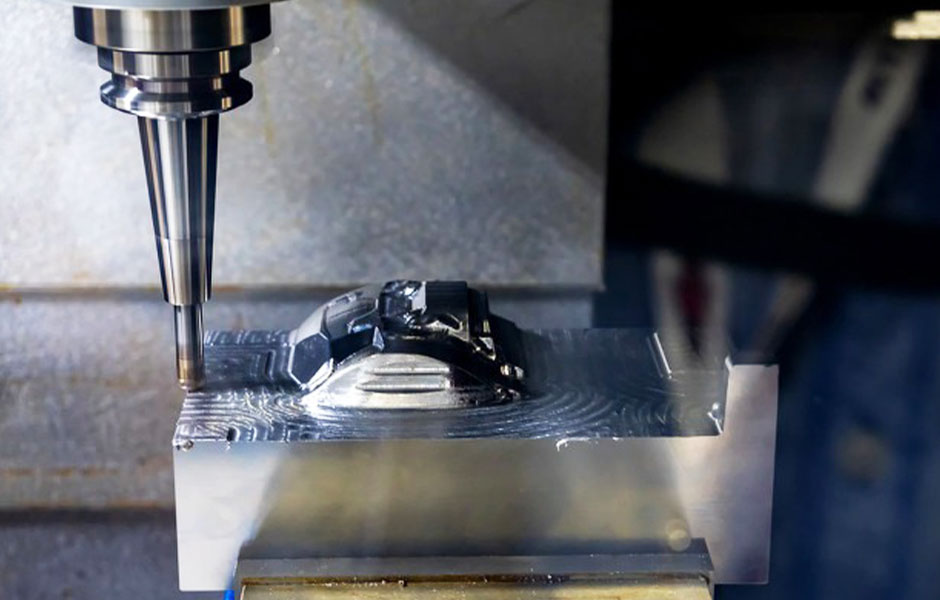

CNC Machining

The CNC machining process is quite different in that it does not use any kind of molten metal as its foundation. In this process, cutting tools are manipulated by computer-controlled machinery to produce many different materials from a variety of metals at high speed without the need for molds or foundries. In the industrial sector, this is a very popular method, and in many ways, it is superior to traditional methods of building metal products.

What Makes Precision CNC Machining a Much Better Choice than Stainless Steel Casting?

Here are the top factors which prove that Precision CNC Machining is a truly better replacement for Stainless Steel Casting:

No Cost Associated with Mold:

With precision CNC machining, you don’t need a mold during prototyping and production. CNC machining is done by using different types of cutting tools that are controlled and operated by using numeric computer codes. This means there is no cost related to mold designing or procurement and thus, you will be saving money.

Complex Shapes and Designs are Possible:

The best thing about precision CNC machining is that you can achieve the most accurate complex designs that would have been quite difficult or even impractical with casting. Casting is not suitable for all those products whose applications higher demand dimensional accuracy and design complexity. It may lead to lots of dimensional errors and a rough surface. However, CNC machining makes it easier with consistent feed, appropriate tooling, and low-tolerance dimensional coding.

Faster Turnaround Cycles:

In most cases, stainless steel CNC machining is a much quicker process to carry out than stainless steel casting. Mold sets take time as it requires time for metal melting as well as cooling. Therefore, the final ejection of products from the mold takes a significant amount of time. On the other hand, in precision CNC machining, the duration is much less for the generation of computer code, setting the workpiece, and post-production ejection of SS products.

High Degree of Dimensional Accuracy and Stability:

As the name suggests, precision CNC machining is widely used for achieving higher dimensional accuracy and stability. Since CNC operations are managed by the computer, it virtually removes human errors. Therefore, stainless steel CNC machining can be used for all those products and applications that require low tolerance for dimensional errors and instability.

On the contrary, stainless steel casting requires extreme heating and cooling that can alter the dimensional accuracy and eventually the stability of the final product. As no extreme heating and cooling are not involved in CNC machining, you can easily rule out the temperature fluctuations in the final product.

Application Of Stainless Steel CNC Machining Parts

Medical Industry

There are too many stainless steel needles, stainless steel scalpels, stainless steel wheelchairs, stainless steel infusion stands, and stainless steel medical tweezers. Especially in the use of orthopedics may be essential every day. Due to the excellent comprehensive performance of stainless steel, the more mature manufacturing technology, and the low price, stainless steel is used more and more widely in the medical field.

The use of stainless steel in the medical field has become a major development trend.

Electronic and Household Industry

Due to the performance of stainless steel, stainless steel has been widely used in other electronic fields. For example, the current water heaters are made of stainless steel for surgery, and the heating tubes of coffee machines are all made of stainless steel. There are others, and you may know in your daily life.

Automotive Industry

The invasion of stainless steel into the automotive sector is almost the biggest. The automotive field is currently the fastest-growing stainless steel application field. Nowadays, the most important manufacturing material for automobiles is basically stainless steel. Mainly used in the body, exhaust system, fuel tank, frame and stainless steel parts, and car decoration. Due to the large demand for stainless steel in automobiles, the automotive field is basically one of the main forces in the development of stainless steel

Stainless steel can also be used in some high-end mechanical fields, such as the food industry, chemistry, medical equipment, aircraft exhaust pipes, etc. Stainless steel has been widely used in industries such as heavy industry, light industry, daily necessities industry, and architectural decoration.

CNC Machining Service

DFM CNC Shop is a CNC manufacturing and sheet metal fabrication company, including CNC machining services, CNC milling services, CNC turning services, laser cutting services, and stamping services.

DFM CNC Shop offers professional CNC machining and rapid prototyping service for making a wide array of product parts. Our excellent quality control systems ensure that all our deliveries are speedy and standard for every manufacturing size in both low-volume and high-volume productions. Feel free to reach out for a free quote on your project.