Computer Numerical Control (CNC) technology has dominated the metal forming industry in recent years, as it offers advanced precision and repeatability that can be impossible to achieve with manual processes alone. With so many CNC technologies on the market, it can be difficult to distinguish between them and what they are used for. While there are many similarities between CNC milling and turning, there are also distinct, important differences.

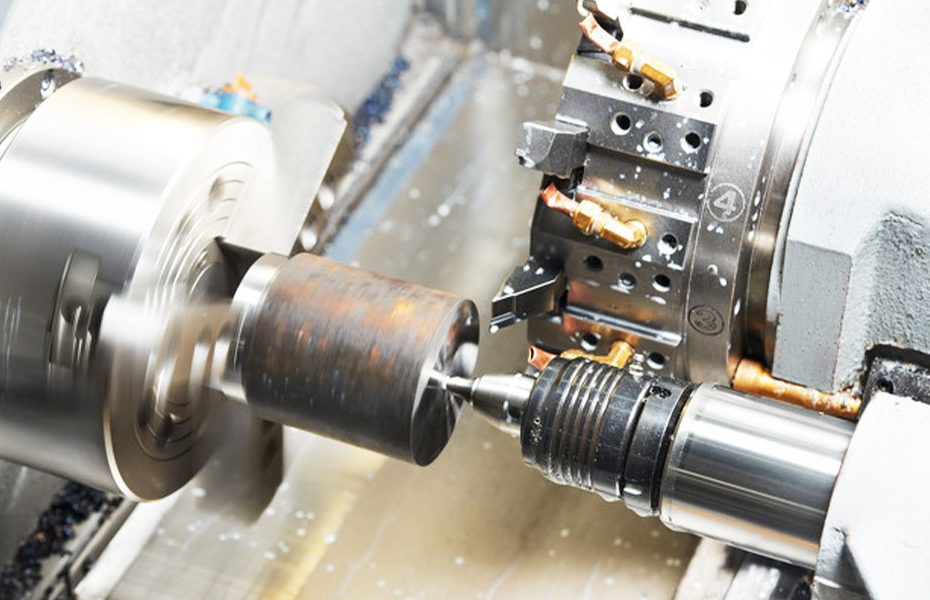

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret (shown center), with tooling attached is programmed to move to the bar of raw material and remove material to create the programmed result. This is also called “subtraction machining” since it involves material removal. If the center has both tuning and milling capabilities, such as the one above, the rotation can be stopped to allow for milling out of other shapes.

Although it is less versatile than CNC milling, it is one of the most popular CNC machining services and rapid prototyping services.

Advantages of CNC Turning

- The biggest advantage of CNC turning is its ability to create round profiles. It is much more difficult to achieve perfect roundness using other CNC machining services like CNC milling or CNC routing.

- CNC turning is also highly accurate, which makes it a valuable technology for boring holes of precise dimensions with set tolerances.

- CNC milling and CNC turning can be combined to reap the benefits of both processes. In most cases, CNC turning takes place first, allowing the machinist to mill further (asymmetrical) details on the part.

While CNC milling is nearly synonymous with CNC machining, CNC turning often produces parts faster and more affordably than milling. CNC milling is limited to the range of motion of the cutting tools. CNC turning is not as good at conserving material but allows for complex design options and faster operations.

CNC Machining Services

Machining services such as CNC milling and CNC turning provide multiple options for the precise fabrication of components and parts. Each method has its pros and cons, making them ideal for different applications.